A Long and Successful History

Thomas and Skinner was founded by John Esterline, an Electrical Engineering professor at Purdue University. Professor Esterline, inspired by the demonstration of commercially viable electricity he witnessed at the Chicago World’s Fair in 1895, recognized the need for permanent magnets to be used for residential and commercial power metering within the burgeoning electrical utility industry. He formed The Esterline Company in Lafayette Indiana, and began producing tungsten and chromium alloy permanent magnets by 1901. Following a catastrophic flood in 1913, the company and all of its employees were moved to Indianapolis and continued to develop and produce magnetic materials.

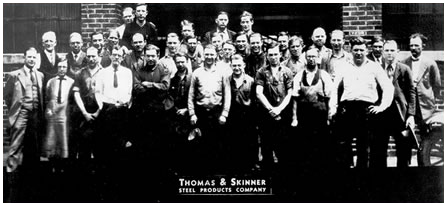

In late 1925, James Thomas and Oramel Skinner purchased the technology and equipment to produce the magnetic material from Prof Esterline and incorporated as Thomas & Skinner Steel Company. The Thomas & Skinner Steel Company added cobalt steel magnets to the existing tungsten and chromium alloy magnet products.

At this same time, the rapidly expanding electrical generation and distribution infrastructure required an ever-larger array of soft magnetic iron core transformers. Thomas & Skinner began to produce stamped transformer laminations from directionally grain oriented silicon steel.

Basic research carried out in the mid 1930’s around the globe, resulted in numerous patents for new permanent magnet alloys. One of the most promising was an alloy created from ALuminum, NIckle, CObalt and Iron, or as it became known as, ALNICO. At this same time discoveries were being made for casting techniques such as pouring molten alloys into heated molds against cold steel chill plates to promote crystalline grain growth, experimentation with heat treatment, specialized magnetic orientation fixtures, rapid quenching and long-term annealing that resulted in superior magnetic properties and temperature stability.

Powdered metallurgy was added to offer the ability to produce ALNICO alloys in a variety of shapes to near finished dimensional conditions with product densities that allow magnetic properties to rival those of cast alloys.

Additional development and refinement of casting techniques, alloy chemistry, heat treatment and magnetic orientation processes has continued throughout Thomas & Skinner’s long history. Today Thomas & Skinner produces sub-grades of the most common ALNICO alloys that are tailored to meet our customer’s specific needs, difficult load lines, or balancing coercive and inductive properties for demanding applications.

A full range of standard sizes and coatings continue to be available for grain oriented transformer laminations. Custom shapes are available in material thicknesses as low as 4 mil.

Tungsten, a metal produced by T&S during the early 1900s, is now being incorporated into T&S tungsten heavy alloys (WHAs). The US market for WHAs is currently dominated by foreign producers, and changes to domestic production requirements for defense items makes this a fast-growing opportunity for a domestic producer like Thomas & Skinner.

Today, Thomas & Skinner, Inc is a 100% employee-owned manufacturer of high performance metals, including magnetic materials, magnetic assemblies and tungsten heavy alloys. Headquartered in Indianapolis, Indiana, T&S is a well-known and respected supplier to the Aerospace, Industrial, Defense, Oil Exploration, and Medical Markets

Contact Us

- 1120 East 23rd St.

Indianapolis, IN 46205 - 317.923.2501

- 317.923.5919

- Info@thomas-skinner.com